Applications And Advantages Of Plastic Pallets

Leave a message

Introduction

Plastic pallets play a crucial role in modern logistics, offering durability, hygiene, and adaptability across various industries. Made from high-density polyethylene (HDPE), they resist moisture, chemicals, and pests, making them a reliable choice for material handling and storage.

Key Applications

Supply Chain & Transportation

Plastic pallets enhance efficiency in loading, unloading, and transport. Their standardized dimensions work seamlessly with forklifts, conveyor belts, and automated systems, ensuring smooth logistics.

Warehouse Management

Interlocking stackable designs optimize warehouse space and integrate with warehouse management systems (WMS) for better inventory control and organization.

Production & Manufacturing

Plastic pallets facilitate automated production lines, reducing manual handling costs and minimizing damage to goods. Their lightweight yet durable construction improves operational efficiency.

International Trade

Unlike wooden pallets, plastic pallets meet ISPM 15 standards, eliminating fumigation requirements and simplifying customs clearance, making them ideal for cross-border shipments.

Food & Pharmaceutical Industries

Certified by FDA and EFSA, plastic pallets provide a hygienic solution for food and medical product handling. Their smooth, non-porous surfaces prevent bacterial growth and allow easy cleaning, ensuring compliance with HACCP regulations.

Advantages

Durability & Strength

Made from reinforced HDPE, plastic pallets offer superior load-bearing capacity and impact resistance. Features like anti-slip surfaces and reinforced edges extend their lifespan.

Environmental Adaptability

Plastic pallets perform well in extreme conditions. Cold-resistant models maintain integrity in freezing environments, while UV-stabilized coatings protect against outdoor wear.

Hygiene & Maintenance

Non-porous surfaces prevent dirt buildup and bacteria growth. Many models support CIP (clean-in-place) systems, ensuring easy maintenance and compliance with hygiene standards.

Sustainability & Cost Efficiency

Plastic pallets are reusable and fully recyclable, reducing long-term costs and environmental impact compared to wooden alternatives. Their durability lowers replacement frequency, aligning with sustainability efforts.

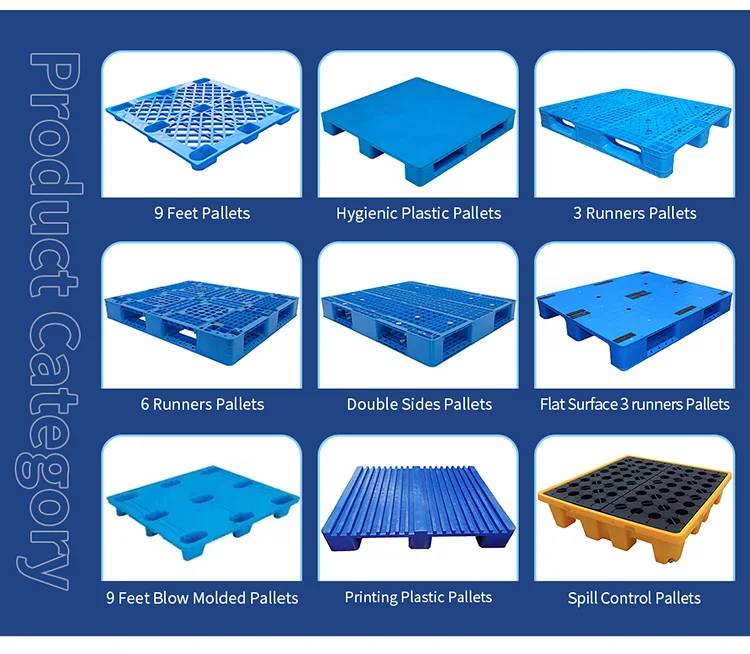

Types & Specifications

By Structure

Nestable Pallets – Space-saving, lightweight HDPE designs, ideal for retail and e-commerce.

Rackable Pallets – Reinforced for stability in storage racks, supporting up to 2 tons.

Heavy-Duty Pallets – Built for industrial use, featuring double-layered PP or steel reinforcements.

By Application

Standard Pallets – General-use HDPE models with standard dimensions.

Cold Storage Pallets – HDPE models designed for temperatures as low as -25°C, used in frozen food logistics.

Industry-Specific Customization

Manufacturing – Color-coded pallets improve organization and workflow.

Automotive – Custom-molded designs secure parts during transport.

Pharmaceuticals – RFID-enabled pallets support real-time inventory tracking.

Chemicals – Corrosion-resistant coatings protect against harsh substances.

Conclusion

Plastic pallets are revolutionizing supply chain operations with durable materials and efficient designs. As industries embrace automation and sustainability, advancements like IoT-enabled tracking and biodegradable bio-plastics will further enhance their role in logistics.